No. 1 VLM Brand in India

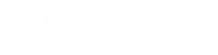

Our vertical Automated storage and retrieval systems with a small footprint, high density, VStoreTM(Vertical Lift Module) makes maximum use of floor and vertical space and offers cost-effective, efficient, quick, and ergonomic solutions to meet your storage and retrieval needs. VStore is a Vertical Lift Module type ASRS completely in-house developed and completely indigenous manufactured in our facility in Coimbatore.

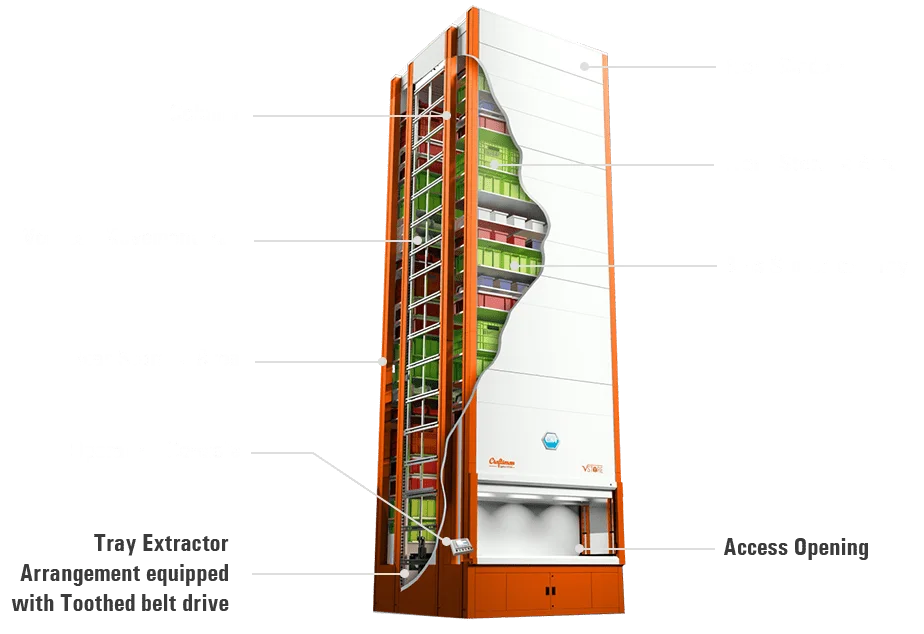

The possibilities of VStore are unlimited. This type of Automated storage and retrieval system can be deployed in various industries such as automotive, electronics, manufacturing, health-care, retail, logistics and warehousing. Wherever items need to be stored with effective usage of space and retrieved quickly, VStore provides the optimum solution.

Send Enquiry

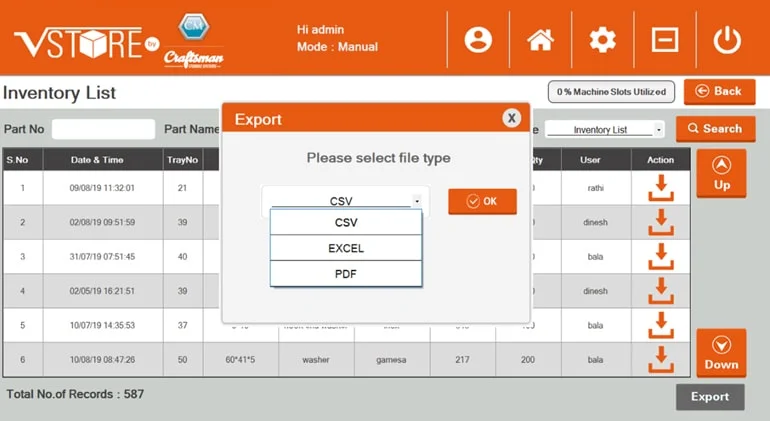

VStore software is exclusively developed by CAL to set up a communication platform for the user to communicate with machine

VStore software has an ability to integrate with different type of ERP system that the customer use

VStore application predominantly runs on industrial computer and communication between the application and the VStore hardware is well established to enable the user for a fine operation of the machine

VStore software gives the user information about the parts stored, inventory, space available in the machine and has features to view call history, scheduling the fetching and various access controls

Every screen of the software is designed with paramount care to make a friendly atmosphere for the user to communicate with the machine

By pressing this icon on the user login screen, the user can login to the software with the help of their registered fingerprints

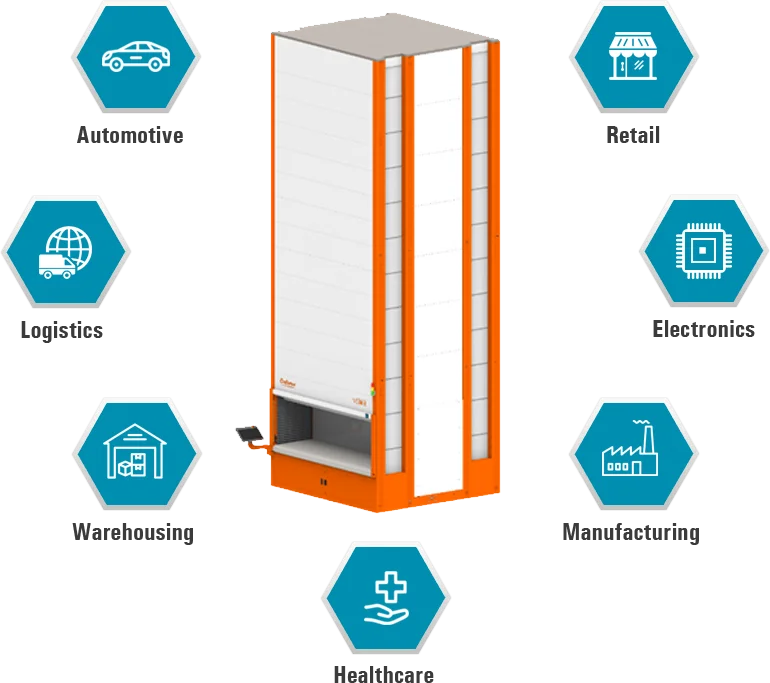

User interaction with the VStore machine through the VStore software is done with the help of the following keypad interfaced with the software

All reports can be exported in three different formats. They are CSV, Excel and PDF

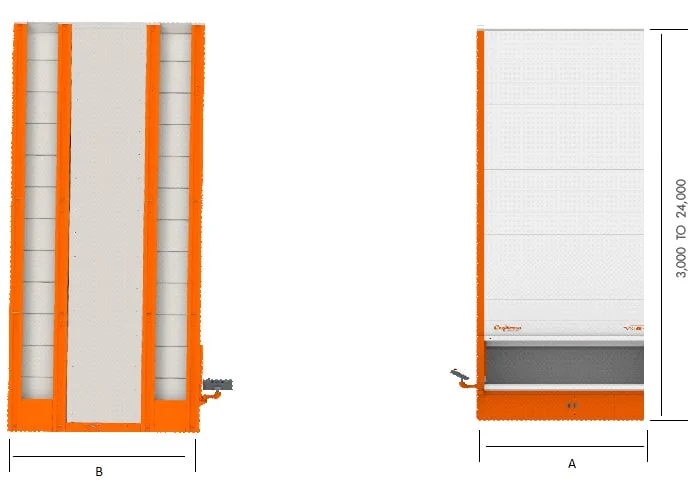

| TECHNICAL DATA | ||||||||

|---|---|---|---|---|---|---|---|---|

| UNIT & TRAY DIMENSIONS | ||||||||

| S.No | Tray Width in mm | Tray depth in mm | Load Capacity | Unit Width in mm A | Unit Width in mm B | |||

| Load Capacity kg (Regular) | Load Capacity kg (Heavy) | |||||||

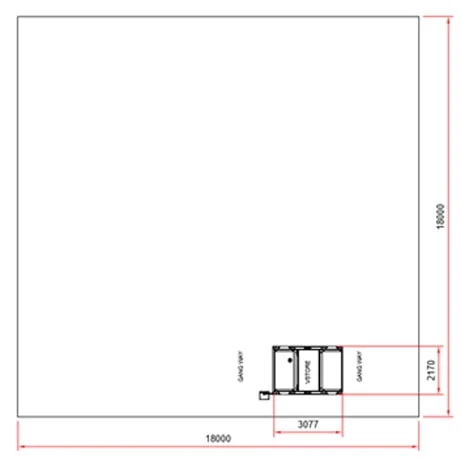

| 1 | 1340 | 865 | 500 | - | 1670 | 3077 | ||

| 2 | 1840 | 2170 | ||||||

| 3 | 2440 | 370 | 500 | 2770 | ||||

| 4 | 2840 | 260 | 465 | 3170 | ||||

| 5 | 3040 | 210 | 3370 | |||||

Tray Adjustment Pitch 50 mm

Tray Pitch 100 mm

| S.No | Tray Width in mm | Load Capacity | Unit Width in mm A | Unit Depth in mm B |

|---|---|---|---|---|

| XXL tray (Depth 825 mm) | ||||

| 1 | 1340 | 1000 | 1710 | 3058 |

| 2 | 1840 | 1000 | 2210 | |

| 3 | 2440 | 900 | 2810 | |

| 4 | 2840 | 850 | 3210 | |

| 5 | 3040 | 800 | 3410 | |

| 6 | 3250 | - | 3620 | |

| 7 | 3640 | 750 | 4010 |

Tray Adjustment Pitch 50 mm

Minimum Tray Distance 150 mm

Unit height - 4050 - 10050mm with an increment of 500mm

Automatic/semi automatic tray extraction for the VStore consists of rigid mechanic construction in the front of access opening of the system

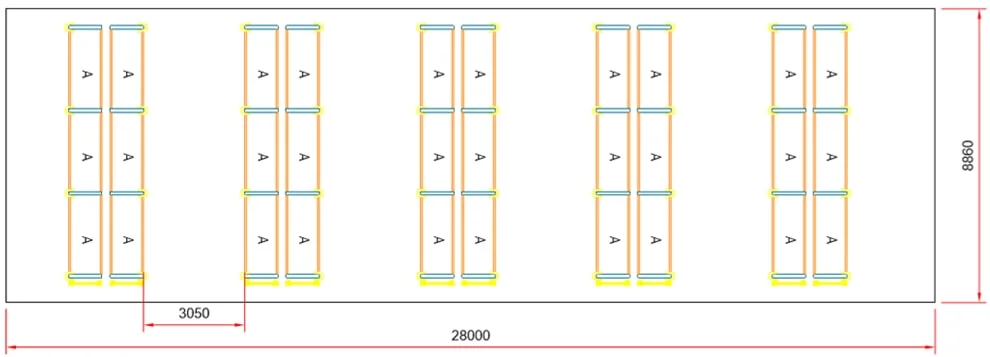

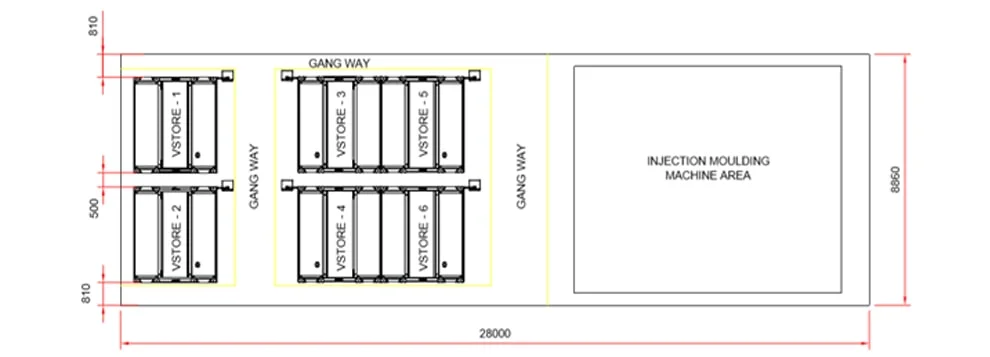

Before using VStore :

250 Sq. m or 2700sqft

(28000 x 8860 x 5000 mm)

Length - 28000 mm

Width - 8860 mm

Height - 5000 mm

After using VStore 6 no’s = 63.24 sq. m

Area occupied by gangway = 17.5 sq. m

Height of the machine = 6.5m

Total area occupied by 6 no’s VStore including

gangway =

80 sq.m (860 sqft)

Floor Space Saving 68%

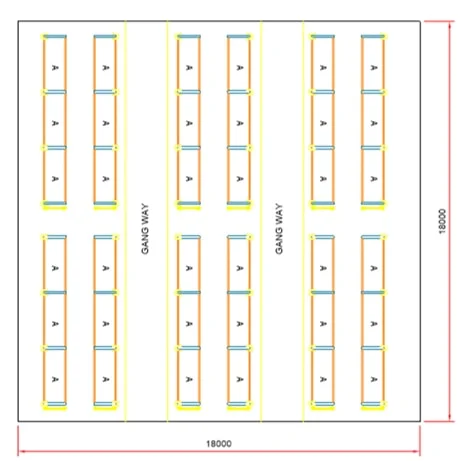

Before using VStore : 324 Sq. m or 3487 sqft

Length - 18000 mm

Width - 18000 mm

After using VStore 1 no’s = 6.67 sq. m

Total height of the machine = 12m

Total area occupied by VStore including gangway : 10 sq. m or 108 sqft

Floor Space Saving 96.91%

Cutting Tool Manufacturer

Previously it is stored inside a mobile compactor, There was no proper tracking of die sets, difficult to trace & chances of misplacing.

View More

Manufacturer

Earlier customer was using 102.19 sq m of area for storing the bins and cartons which includes smaller line items as well as regular inventory.

View More

Industry

In process of the makeover of their existing traditional stores to advanced space optimization solution, Cyient Dlm was marching ahead.

View More

Industry

The world's leading manufacturer of agricultural, construction and forestry equipment company Headquartered at Pune

View More

Industry

A fully owned subsidiary of Japan Rubber Company, which is a leading name in the global Off-Highway Tires business. The Company develops, manufactures...

View MoreWe are always happy to answer any questions. Just fill in the form and we will get back to you