Drive in Racking

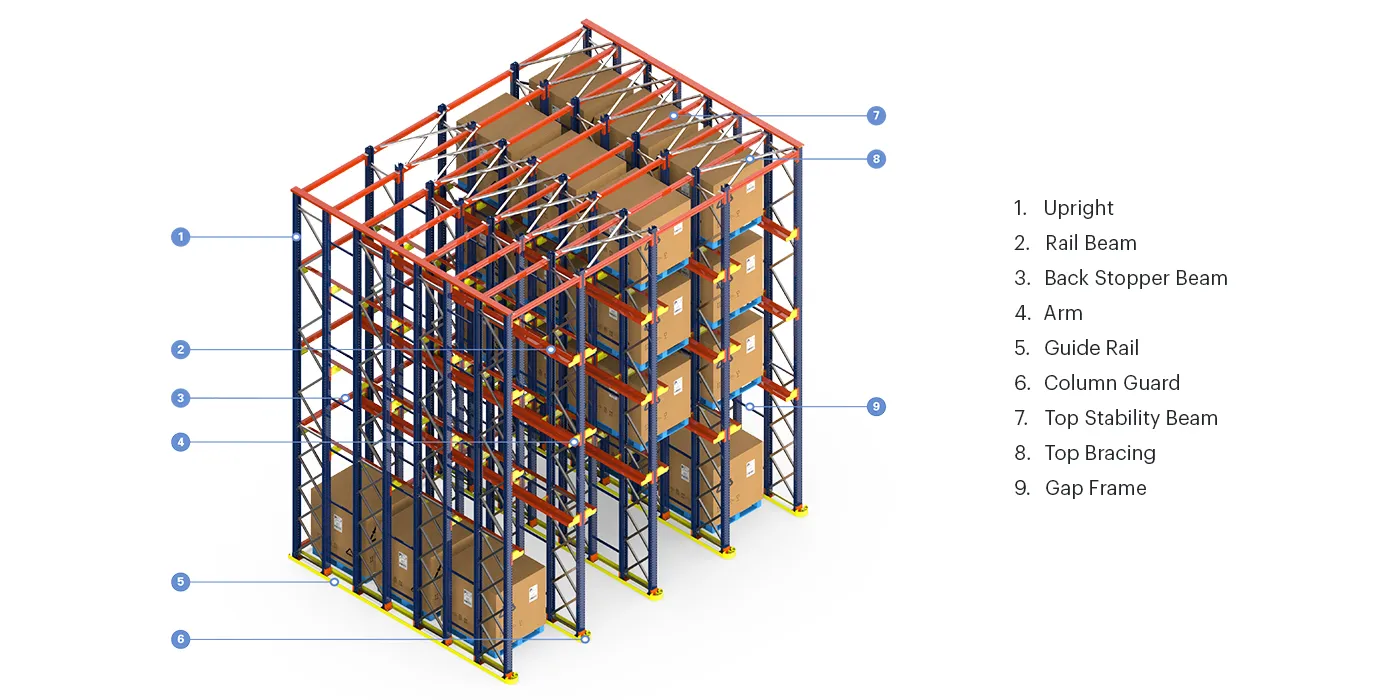

Craftsman’s drive-in racking is constructed using the same frames as our existing pallet racking system and is equally capable of supporting high loads. Material Handling Equipment drives into the aisle to store & retrieve pallets.

Tap to View

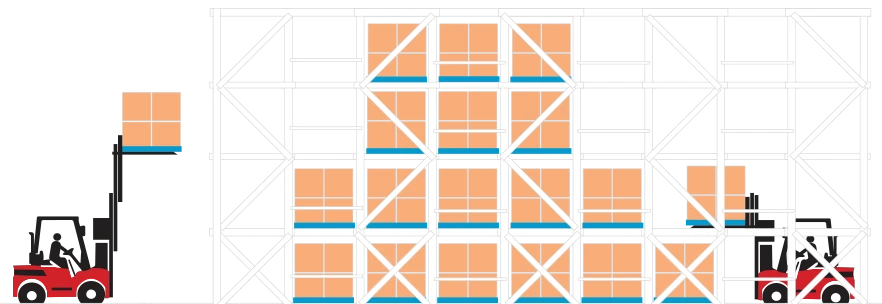

Pallets are typically loaded and unloaded from the same side in drive-in racking, which follows the LIFO (Last In, First Out) principle. Our framework also allows for FIFO ( First In, First Out ) principle when pallets are loaded on one side and unloaded from the other.View More

The Drive-in Rack with the help of MHE maximizes surface area and storage space by driving into the aisle and placing pallets from back to front on storage rails that extend entirely from one side of the rack to the other. Drive-in Racks allow you to store a large number of similar SKUs in a small space. Drive-in racking from Craftsman is an ideal dense storage solution for homogeneous products with a large number of pallets per SKU. Our Drive-in Rack is equipped with guide rails and column protection guards for safe operations. View Less

Side View

Product Gallery

Advantages

- Drive in racking systems increase storage density by eliminating aisles and are multiple pallet positions deep.

- It allows configuration for both FIFO and LIFO management making it a versatile type of racking solution.

- Eliminates the service aisles found with a conventional pallet racking system.

- Ideal for homogeneous products with a large number of pallets of the same reference, and with a low turnover.

- Our galvanised rolled rails offer superior torsion resistance and resist abrasion.