Harnessing Efficiency: Warehouse Automation in the Solar Energy Revolution

In today's rapidly advancing world, the solar energy sector stands at the forefront of sustainable innovation.

Read More

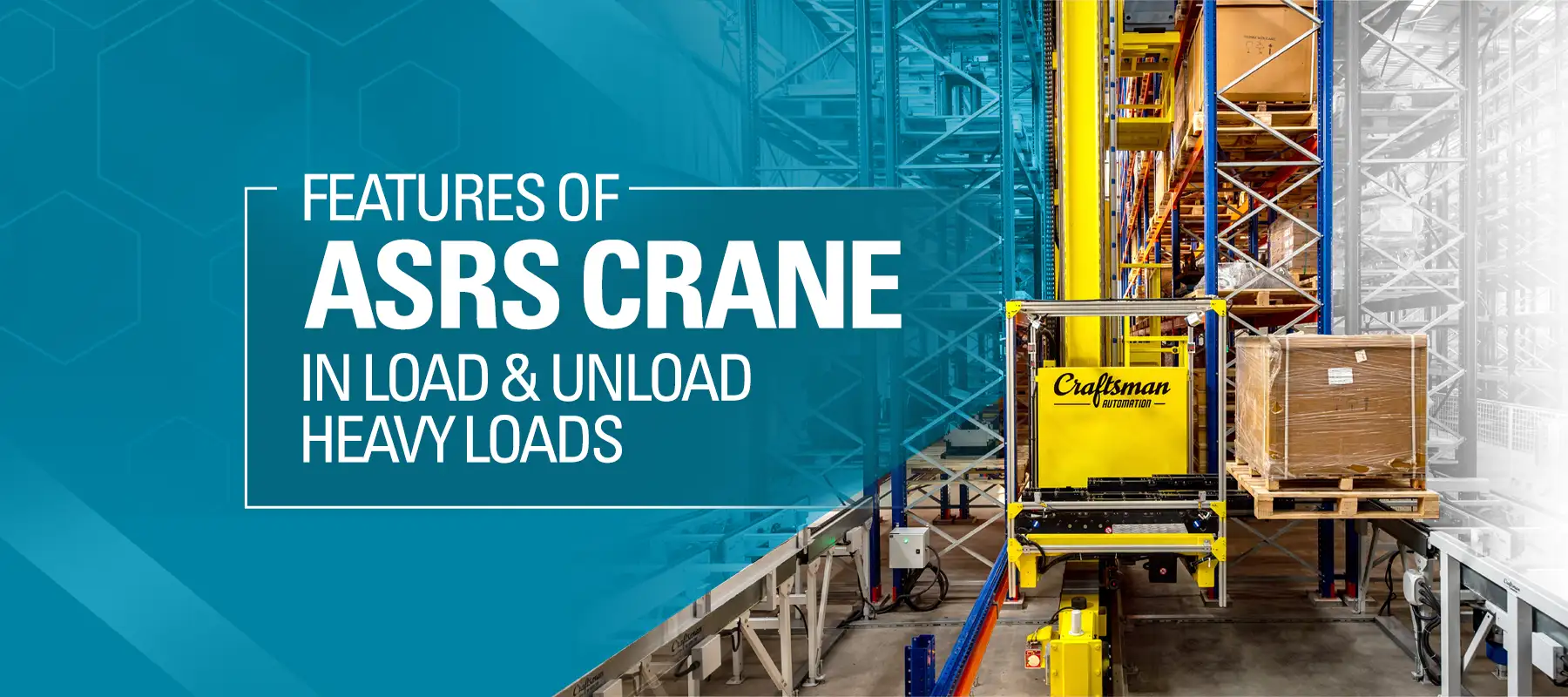

In modern warehousing, efficiently handling heavy loads is essential. Automated Storage and Retrieval Systems (ASRS) cranes offer an innovative solution designed for high performance and precision. These cranes streamline the storage and retrieval process, significantly reducing the time needed to manage inventory. By minimizing human error and maximizing the use of vertical space, ASRS cranes enhance overall warehouse productivity. Their integration with Warehouse Management Systems (WMS) ensures real-time tracking and control of inventory, leading to better accuracy and optimized storage utilization.

Here are some key features and benefits that are crucial for you

Key Features

High Throughput: ASRS cranes are designed to manage up to 40 pallets per hour. This high capacity ensures rapid load processing, significantly speeding up the overall operations in a warehouse. This increased throughput allows businesses to meet high demand and process orders quickly and efficiently.

Stability: Equipped with anti-oscillation devices and tampering programs, ASRS cranes minimize vibrations during operations. This stability is crucial for maintaining the integrity of goods, especially fragile items, and ensures accurate placement and retrieval, reducing the risk of damage.

Storage features : These cranes support both single and double-deep storage configurations. The telescopic forks enable efficient handling of pallets, allowing for greater flexibility in arranging and accessing inventory. This versatility maximizes storage density and optimizes the use of available space.

24/7 Operation: Designed for continuous operation, ASRS cranes can run around the clock without the need for frequent breaks or downtime. This ensures constant productivity and can significantly increase the throughput of warehouse operations, meeting the demands of a fast-paced logistics environment.

Controlled Inventory Management: Integration with Warehouse Management Systems (WMS) provides real-time tracking and control of inventory. This integration enhances accuracy in inventory management, reduces discrepancies, and improves overall efficiency by providing up-to-date information.

Benefits

Increased Efficiency: High throughput and continuous operation boost productivity.

Enhanced Precision: Minimizes the risk of damage to goods.

Optimal Space Utilization: Maximizes use of available space with versatile storage options.

Improved Inventory Control: Real-time tracking reduces discrepancies and improves accuracy.

Investing in Automated Storage and Retrieval Systems (ASRS) cranes can take your warehouse operations to the next level. With the ability to handle up to 40 pallets per hour, these systems ensure rapid load processing. The precision and stability provided by anti-oscillation devices and tampering programs minimize errors and maintain the integrity of goods. Versatile storage options, including single and double-deep configurations, maximize space utilization. Continuous 24/7 operation ensures constant productivity, while integration with Warehouse Management Systems (WMS) offers accurate inventory tracking. ASRS cranes enhance efficiency, accuracy, and productivity in managing heavy loads, making them an invaluable asset in modern warehousing.

Ready to transform your warehouse operations with ASRS cranes?

Start exploring the benefits today.